While most people don’t give much thought about how goods are tracked and end up on store shelves in places like Walmart, a senior electrical engineering student at NDSU has been doing just that in his undergraduate research experience.

Fargo native Layne Berge is part of a team at NDSU’s Center for Nanoscale Science and Engineering that’s developed an antennaless radio frequency identification tag. The technology could eventually help businesses maximize supply chain management, tracking everything from barrels of oil to metal cargo containers.

|

| Layne Berge |

Tracking and identifying metal objects can prove difficult for some radio frequency identification systems. The patent-pending antennaless radio frequency identification tag technology developed by a research team at the Center for Nanoscale Science and Engineering at NDSU could solve these tracking problems.

A typical radio frequency identification tag is made up of an integrated circuit and an antenna. While there are different types of tags available, many don’t work well on metal objects or on containers filled with liquid. Previous attempts to solve this problem have resulted in bulky tags that are easily destroyed by routine handling. Researchers at NDSU’s center have developed a patent-pending novel approach, with an antennaless radio frequency identification tag, allowing for an inexpensive and manufacturable product tracking solution that meets EPCglobal Standards.

The NDSU research team includes Cherish Bauer-Reich, research engineer; Michael Reich, senior research engineer; and Berge. The group’s research will be presented at an international workshop on antenna technology scheduled for March 5-7, in Tucson, Ariz., with presenters from more than 15 countries expected to participate in the event. The research presentation titled “Low-profile, high-permeability antennaless RFID tags for use on metal objects” is scheduled for March 5.

|

| Cherish Bauer-Reich |

|

| Michael Reich |

Berge’s contribution to the team included building the prototype tag designs and testing the tags. As an undergraduate at NDSU’s center, Berge is involved in many such projects. “While this is one of the most fascinating, the utility from these experiences is the ability to witness how what I learn in the classroom actually applies to real-life engineering problems,” he said. The tags that Berge helped to develop are unique.

“Most RFID tags that are to be used on metal objects are made by placing an antenna on a spacer, making them between 0.5 and 3 cm thick, depending on the type of tag,” said Bauer-Reich, research engineer leading the project. Such tags can be easily damaged because they stick out so far. The tags developed by NDSU’s center are less than 3 mm thick and are placed directly on the metal, or could be recessed into the surface of a metal container.

|

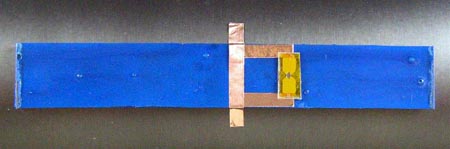

| A new type of radio frequency identification (RFID) tag doesn't have an antenna of its own, but instead uses the metal object that it's attached to as its antenna |

“The tags we’ve developed actually use the metal container as an antenna, rather than having to make and place another antenna on top of the container,” said Bauer-Reich. “Many types of tags have to be spaced away from metal, since it changes the electromagnetic fields around the tags and destroys their ability to communicate. These tags can be used to tag anything from coffee cans at a grocery store to barrels of oil or metal cargo containers, with minimal concern about losing or damaging the tag.”

|

| One of the antennaless RFID tags, on a metal flask |

High-permeability materials divert current into the tag’s integrated circuit. Tags using high-permeability materials in such a way are significantly thinner than those developed using other methods.

Berge found the process of developing the antennaless tags valuable. “I learned how to think out-of-the-box in regard to antennas,” he said. “The ability to see how the RFID tag operated through the use of simulation tools helped us to better design the tag. I believe the capabilities of simulation tools, not only to predict performance, but also to complete the testing and redesign process, is the most important thing I learned, along with thinking beyond the current standards,” he said.

Berge thinks his more than three years of experience in state-of-the-art labs at NDSU’s center will make a difference in his career path. Upon receiving his undergraduate degree, Berge plans on pursuing a master’s degree at NDSU in electrical engineering.

The antennaless radio frequency identification tag technology developed at NDSU’s center was developed with support under Grant Number N00189-10-C-Z055, awarded by the U.S. Department of Defense, Office of Naval Research.