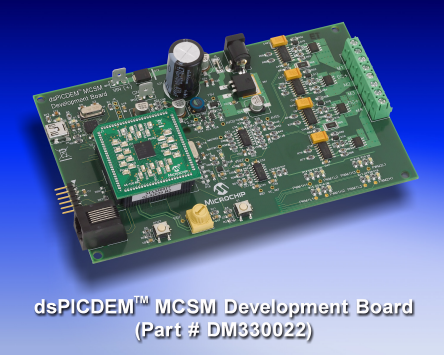

Development Kit Microchip dsPICDEM MCSM (DV330021)

The Microchip dsPICDEM MCSM Development Board is targeted to control both unipolar and bipolar stepper motors in open-loop or closed-loop (current control) mode.

Detailed Description

The hardware is designed in such a way that no hardware changes are necessary for 8-, 6- or 4-wire stepper motors in either bipolar or unipolar configurations. Software to run motors in open-loop or closed-loop with full or variable micro-stepping is provided. A GUI for controlling step commands, motor parameter input, and operation modes is included. This flexible and cost-effective board can be configured in different ways for use with Microchip’s specialized dsPIC33F Motor Control Digital Signal Controllers (DSCs). The dsPICDEM MCSM Development Board offers a mounting option to connect either a 28-pin SOIC device or a generic 100-pin Plug-In Module (PIM). A dsPIC33FJ32MC204 DSC PIM (MA330017) is included.

dsPICDEM MCSM Development Kit: DV330021

- dsPICDEM MCSM Development Board

- dsPIC33FJ32MC204 Plug-In-Module (PIM)

- USB-to-mini-USB cable

- Screwdriver

- dsPICDEM MCSM Development Board CD ROM, including:

- MCSM User’s Guide

- Data sheets for dsPIC DSC families

- Application Note with software and MPLAB DMCI/RTDM GUI for Stepper Motor Control

- 24V Power Supply

- Lead Shine Stepper Motor (P/N: AC300024)

The dsPICDEM MCSM Development Board supports terminal voltages up to 80V and currents up to 3A. The dsPIC33F device uses the MOSFET driver to drive the two full-bridge inverters that power the motor windings. The board includes various circuitries to perform the following functions:

- Drive two motor windings with the two on-board full-bridge inverters

- Measure feedback and other analog signals (i.e., current, DC voltage, Potentiometer and Fault signals)

- Communicate with a host computer or an external device via USB

The dsPIC DSC devices feature an 8-channel, high-speed PWM with Complementary mode output, a programmable ADC trigger on the PWM reload cycle, digital dead time control, internal shoot-through protection and hardware fault shutdown. These features make the dsPIC DSC an ideal solution for high-performance stepper motor control applications where control of the full-bridge inverter is required.

Key Features:

- Motor control interfaces:

- Two full-bridge inverters

- Two phase current sense resistors

- DC bus voltage sense resistor

- Over-current protection

- Built-in power supplies:

- 15V power supply, maximum power available 11 W

- 3.3V power supply, maximum power available 2 W

- Power supply connectors:

- 24V power input connector (J6) for the controller and power stage

- Auxiliary Power Tab Fast-On connectors (BP1 and BP2) for the power stage

- Motor control device (U2) socket:

- The dsPIC33FJ12MC202 Motor Control device in SOIC package (U3) footprint

- User Interfaces:

- One push button (S1)

- Reset push button (RESET)

- 10K Ohm Potentiometer (POT)

- LED indicators for PWM outputs arranged in a full-bridge format

- LED indicator for over current

- Communication Ports:

- UART communication via USB (J4)

- Programming Connectors:

- ICSP connector for programming a dsPIC DSC device (J2)

- RJ11 connector for programming a dsPIC DSC device (J1)

- ICSP connector for programming the PIC18LF2450 USB-to-UART Bridge (J3)