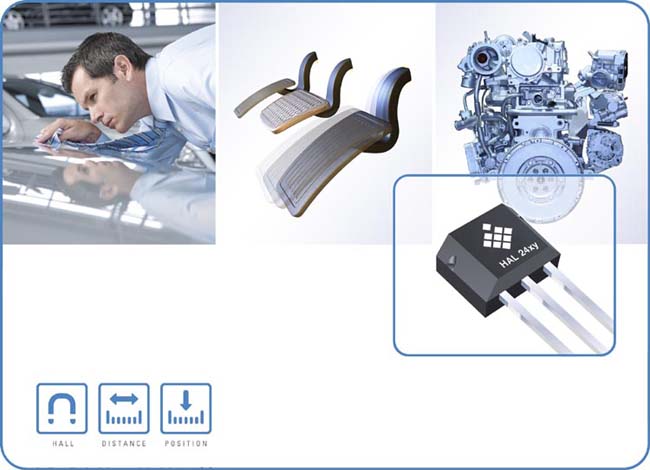

The new HAL 24xy family offers extended distance measurement, smaller magnet dimensions, improved robustness and state-of-the-art diagnostic functions for stringent automotive and industrial applications.

Micronas announced the HAL 24xy family of high precision programmable linear Hall-effect sensors designed to match the performance, diagnostic and reliability requirements of today’s most demanding automotive applications.

The new HAL 24xy family uses Micronas’ latest technology node, a new digital architecture as well as further improved Hall plates. All new family members will leverage upon Micronas’ long success in linear Hall-effect sensors, full in-house manufacturing and automotive-proven zero-ppm track record.

Like its predecessors, the HAL 24xy family has an integrated non-volatile memory to store all sensor parameters. Proven in previous generations of Micronas Hall-effect sensors, this memory is extremely robust and reliable, up to a maximum junction temperature of 170 °C.

The sensor’s high accuracy is based on a sophisticated 16-bit signal path with an integrated DSP core delivering a ratiometric 12-bit analog output signal. Micronas’ designers put extra effort to maximize the sensitivity and minimize the offset drifts over the whole temperature range. This guarantees long-term stability of critical parameters, which ensures the car’s optimum performance for many years. Electrostatic discharge (ESD) is a severe issue in automotive applications and the 8-kV (HBM) rating of the HAL 24xy significantly surpasses other existing linear Hall-sensors in the market today.

Moreover, all new HAL 24xy family members feature enhanced diagnostic functions to improve the detection and identification of potential errors thus facilitating implementation of our customer fail-safe strategy. One first set of features allows the ECU to detect and report problems with the car’s wiring through wire break detection for supply and ground line. Short circuit at the output stage is easily detectable thanks to a dedicated undervoltage detection and thermal supervision.

Another set of features enhances error diagnostic coverage and is extremely valuable in safety critical automotive applications. It provides supervision and internal self-tests of the whole sensor signal path and memory map: A specific EEPROM check is done at each power-on and in addition, a ROM parity check and different state machine self-tests run continuously during normal operation.

All HAL 24xy family members simplify customer programming operations and make them more robust. Unlike other sensors on the market, the HAL 24xy does not need a dedicated programming pin. Instead commands are sent directly via the bi-directional output pin. A robust programming is further guaranteed thanks to various integrated protection features: A CRC (Cyclical Redundancy Check) monitors the communication protocol. The supervision of the supply and the internal programming voltages as well as the monitoring of the programming time ensure that an operation is successfully performed. Furthermore, the HAL 24xy family uses standard TTL level programing voltages, eliminating the need for a dedicated power supply.

A development board to ease design and production activities is available together with a LabView™ based programming software.

All members of the RoHS-compliant HAL 24xy family are available in the TO92UT package, suitable for overmolding, and operate at ambient temperatures between –40°C and +160°C. The whole family is designed for harsh industrial and automotive applications (junction temperature up to 170°C) and operates with standard 5 V supply voltage. Furthermore, all family members are fully qualified according to the automotive standard AECQ100.

The first member of the family to be introduced to the market will be the HAL 2420, featuring an analog output without set points. Samples will be available in September 2012. Start of production is in early 2013.