Fujifilm Corp developed a new recording method for optical discs by using two-photon absorption to generate heat

Fujifilm confirmed that the method realizes a recording density of 25 Gbytes per layer, which is equivalent to the recording density of Blu-ray Disc (BD), and 20 layers per side of a disc. Therefore, with the method, it is possible to make a double-sided optical disc whose storage capacity is 1 Tbyte. The company aims to commercialize the disc by 2015.

Moreover, the new recording method has a potential to realize a 15-Tbyte disc in the future and a cost as low as a magnetic tape.

Large capacity

As for the capacity, the new method uses a two-photon absorption phenomenon, which is suited for multilayer discs. Because the reaction caused by the two-photon absorption can be limited to the small area of the focal point of a laser light, it is possible to increase the number of recording layers.

There are other researches on the use of a two-photon absorption phenomenon. But, unlike the past researches, Fujifilm combined a two-photon absorption phenomenon with the "Heat-mode Recording" method. The Heat-mode Recording is a technology that exploits a phenomenon in which an irreversible change is caused by applying a laser light with a high energy density to instantaneously increase the temperature of a minute area of a recording material.

|

|

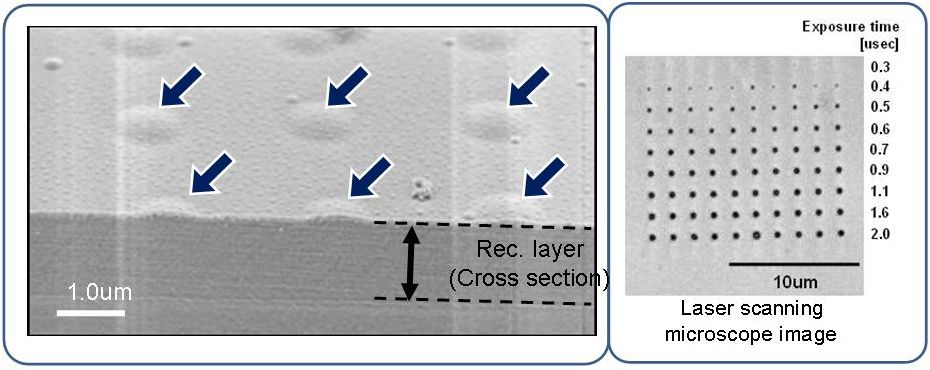

An SEM image of the convex-shaped mark |

A recorded mark having a convex shape is formed on the part where the laser light is applied. This time, Fujifilm used a Ti/S laser (405 nm, 76 MHz, 2 picoseconds). The numerical aperture (NA) of the optical system is 0.85.

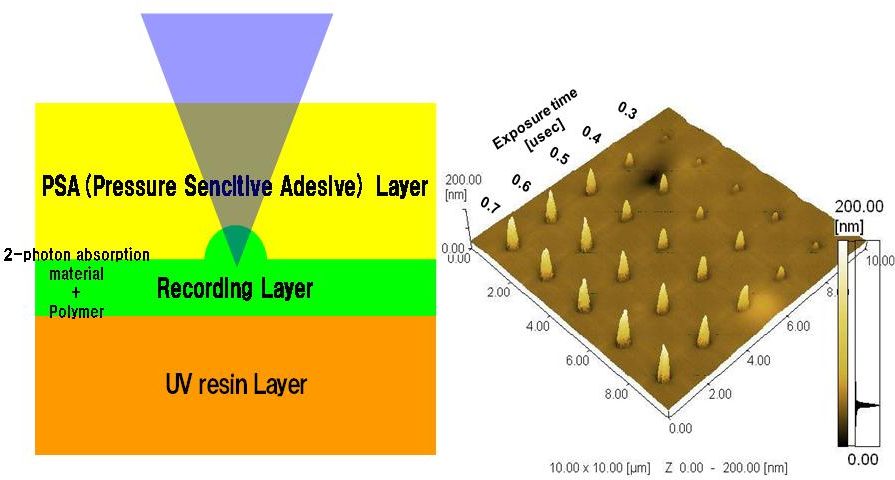

The recording element made with the new method consists of a recording layer on which the convex-shaped mark is formed by applying the laser light and ultraviolet curable resin and adhesive material layers that sandwich the recording layer. Recorded data is read out by detecting the change of the amount of light reflected on the interface between the recording layer and the adhesive material layer.

In the recorded area, surface scattering and diffraction occur due to the convex-shaped mark. Therefore, "High-to-Low Polarity" (two values), which lowers reflectance ratio more than in the area where no data is recorded, is used for modulation. The recording layer and the ultraviolet curable resin layer have almost the same refractive index so that reflection does not occur on the interface between the two layers. In addition, the height of the convex-shaped mark can be controlled by changing the irradiation time of a laser light.

"Currently, two values are realized by the existence of the convex-shaped mark," Fujifilm said. "But, for the future, it might become possible to realize four values by using four states of the mark (2x recording capacity) and eight values by using eight states of the mark (3x recording capacity)."

|

|

The structure of the two-photon absorption material (left) and the variation of the convex shape depending on the irradiation time of a laser light (right) |

Furthermore, Fujifilm used a two-photon absorption material with a high light transmittance. The light transmittance of a prototype with 20 recording layers was 87%. Based on this result, the company estimates that about 50% light transmittance will be ensured with 100 layers. With existing BD technologies, transmittance is lowered to about 65% with four layers, it said.

"In the future, it will be possible to realize a 15-Tbyte optical disc (25 Gbytes/layer x 3 (eight values) x 100 layers x 2 (two sides)," Fujifilm said.

Low cost

As for the low cost, Fujifilm simplified the manufacturing process by using "Web coating" to form the recording, ultraviolet curable resin and adhesive material layers and sticking them together. In the case of BD, spin coating and sputtering have to be conducted for each layer.

"It takes 147 seconds to form a four-layer BD," the company said. "With our method, it takes only 58 seconds to form eight layers."

The competitors of the new disc are hard disk drives (HDDs) and magnetic tapes. The former is expensive, but its access speed is as fast as several milliseconds. The latter is inferior to HDDs in terms of access speed but has a cost (including maintenance) about 1/3 that of HDDs.

|

|

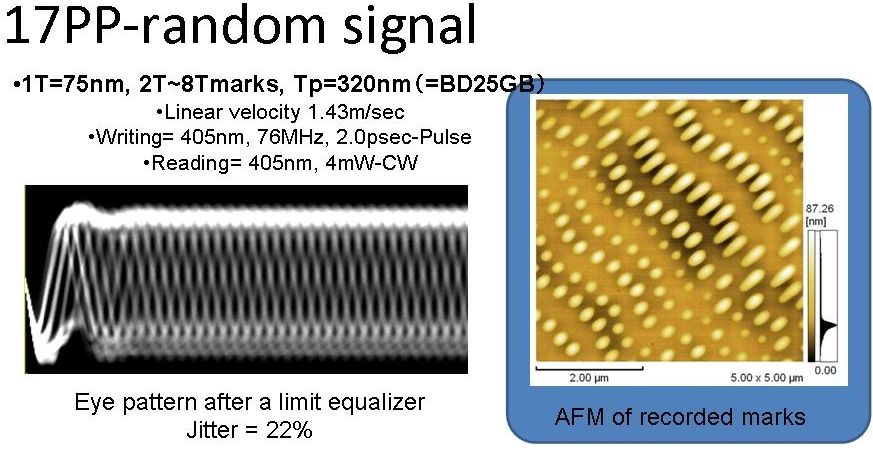

Wtiting and reading with the 17PP encoding technology |

Therefore, HDDs are used mainly for saving and handling specific files with small sizes while magnetic tapes are used mainly for the backup of large-size data with high transmission speeds. On the other hand, the two-photon absorption disc has a cost as low as that of a magnetic tape and a fast access speed, Fujifilm said. The access speed is about several ten to hundred milliseconds.

The problem for the commercialization of the disc is the low reflectance ratio (0.5%) of playback signals. The ratio is only 1/40 that of BD (20%). Fujifilm confirmed writing and reading with the 17PP encoding technology, which is also used for BD.

"We will continue the development of the disc with help from drive makers," the company said.