Featuring Silicone Lens, Device Provides Energy-Saving Replacement for Mercury Lamps in Medical, Industrial, and Printing Applications

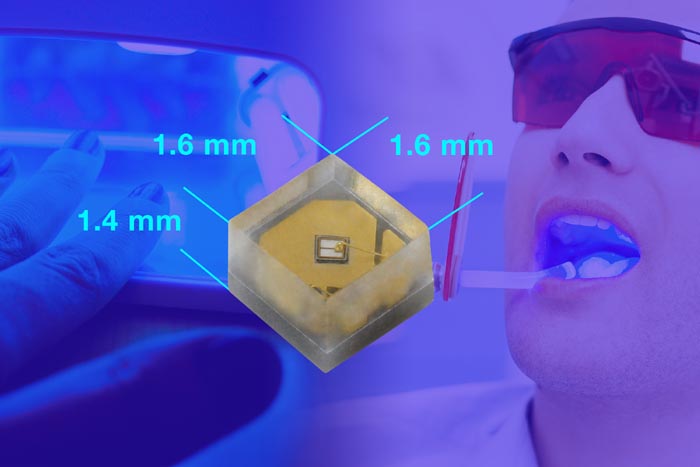

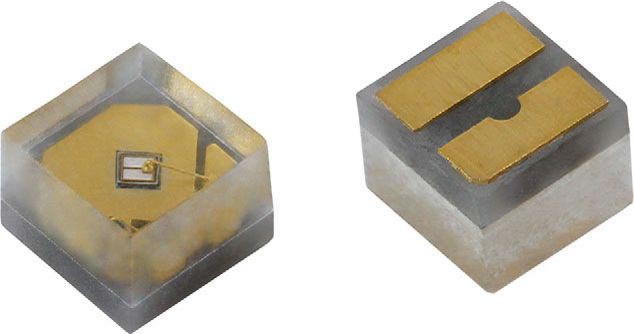

Vishay Intertechnology expanded its offering of mid-power UV LEDs in the 365 nm wavelength range with a new device featuring a silicone lens in a compact 1.6 mm by 1.6 mm by 1.4 mm surface-mount package. Designed to provide a reliable, energy-saving replacement for mercury lamps, the Vishay Semiconductors VLMU1610-365-135 delivers an exceptionally long lifetime for medical, industrial, and printing applications.

The silicone lens of the VLMU1610-365-135 enables extremely long lifetimes up to 25,000 h, compared to the typical mercury lamp lifetime of 10,000 h. The environmentally friendly UV LED is free of heavy metals and provides increased reliability with its shock resistance and immunity to degradation from frequent on / off switching. While mercury lamps require complex drive circuits and need two to 15 minutes to warm up, the VLMU1610-365-135 allows for the use of simple low-voltage circuitry and requires no warm-up period.

Built on InGaN (indium gallium nitride) technology, the device released today features typical radiant power of 18 mW at 20 mA and 50 mW at 60 mA in a wavelength range between 362.5 nm and 370 nm. The VLMU1610-365-135 offers an emission angle of 135°. The LED’s specifications make it ideal for UV curing in nail salon, dental, and poster printing applications; blood and counterfeit money detection; and photocatalytic purification.

RoHS-compliant, halogen-free, and Vishay Green, the VLMU1610-365-135 is compatible with reflow soldering processes and features a Moisture Sensitivity Level of 3 in accordance with J-STD-020.

Samples and production quantities of the new UV LED are available now, with lead times of six to eight weeks.