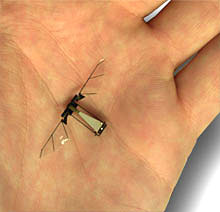

A life-size, robotic fly has taken flight at Harvard University. Weighing only 60 milligrams, with a wingspan of three centimeters, the tiny robot's movements are modeled on those of a real fly. While much work remains to be done on the mechanical insect, the researchers say that such small flying machines could one day be used as spies, or for detecting harmful chemicals.

Some extremely small parts can be made using the processes for creating microelectromechanical systems. But such processes require a lot of time and money. Wood and his colleagues at the University of California, Berkeley, needed a cheap, rapid fabrication process so they could easily produce different iterations of their designs.

Ultimately, the team developed its own fabrication process. Using laser micromachining, researchers cut thin sheets of carbon fiber into two-dimensional patterns that are accurate to a couple of micrometers. Sheets of polymer are cut using the same process. By carefully arranging the sheets of carbon fiber and polymer, the researchers are able to create functional parts.

For example, to create a flexure joint, the researchers arrange two tiny pieces of carbon composite and leave a gap in between. They then add a sheet of polymer perpendicularly across the two carbon pieces, like a tabletop on two short legs. Two new pieces of carbon fiber are placed at either end of the polymer, as a final top layer. Once all the pieces are cured together, the resulting part resembles the letter H: the center is flexible but the sides are rigid.