Highest accuracy, smallest size and best harsh media compliance will significantly contribute to a better environment.

Melexis announces a new highly accurate pressure sensor intended for harsh media applications, especially in the automotive sector.

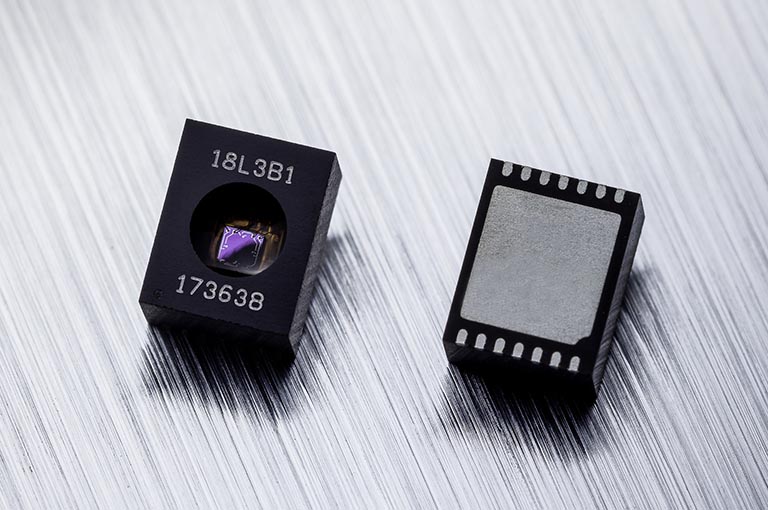

The new MLX90818 is a packaged absolute pressure sensor that is factory-calibrated to cover the range 1.0 to 5.5 bar, making it ideal for normally aspirated, direct injection and turbocharged engine applications. The highly integrated sensor includes provision for an external NTC for temperature measurement and is housed in a tiny 4 × 5 mm DFN package. Already the smallest device available today, the MLX90818 requires very few external components, allowing OEM to easily develop small and rugged Manifold Air Pressure (MAP) sensors.

As the only component solution available without exposed corrodible metals, the device offers the best harsh media compliance, especially against the harsh halogens found in high concentrations in modern engines that are both downsized and lighter. The MLX90818 has 18 V overvoltage capability and can operate from –40 °C to +150 °C making it suitable for all under-the-hood applications.

Pressure accuracy is a market-leading ±0.5% to ±0.75% for extended life operation at 150 °C, allowing highly accurate MAP and EGR sensors to be built, thereby reducing significantly the NOx emissions that contribute to pollution and the CO2 emissions that contribute to global warming.

The output from the sensor is fully compliant with the J2716 Single Edge Nibble Transmission (SENT) protocol and allows easy and rapid customisation of the configuration to suit different customer needs.

The MLX90818 is available factory-calibrated from Melexis and customers can configure the device for low volume applications through the application pins using proven software tools available directly from Melexis.