Introduction

Flyback converters are widely used in isolated DC/DC applications because of their relative simplicity and low cost compared to alternative isolated topologies. Even so, designing a traditional flyback is not easy – the transformer requires careful design, and loop compensation is complicated by the well known right-half plane (RHP) zero and the propagation delay of the opto-coupler.

Linear Technology’s no-opto flyback converters, such as the LT3573, LT3574, LT3575, LT3511 and LT3512, simplify the design of flyback converters by incorporating a primary-side sensing scheme and running the converter in boundary mode.

The LT8300 high voltage monolithic isolated flyback converter further simplifies flyback design by integrating a 260 mA, 150 V DMOS power switch, an internal compensation network and a soft-start capacitor. The LT8300 operates with input supply voltages from 6 V to 100 V and delivers output power of up to 2 W with as few as five external components.

The LT8300 operates in boundary mode and offers low ripple Burst Mode® operation, enabling the design of converters that feature high efficiency, low component count and minimal power loss in standby.

Simple and Accurate Primary-Side Voltage Sensing

|

|

| Figure 1. | A Complete 5 V Flyback Converter for a 22 V to 75 V Input. |

The LT8300 eliminates the need for an opto-coupler by sensing the output voltage on the primary side when the output diode current drops to zero during the primary switch-off period. This greatly improves the load regulation since the voltage drop is zero across the transformer secondary winding and any PCB traces. This allows an LT8300-based flyback converter to produce ±1% typical load regulation at room temperature. Figure 1 shows the schematic and Figure 2 the load regulation curves of a flyback converter with a 5 V output.

|

|

| Figure 2. | Regulation of a 22 V to 75 V Input to 5 V Flyback Converter of Figure 1. |

Very Small Size, Low Component Count Solution

The LT8300 integrates a 260 mA, 150 V DMOS power switch along with all high voltage circuitry and control logic into a 5-lead TSOT-23 package. The isolated output voltage is set via a single external resistor with compensation and soft-start circuitry integrated in the IC. Low ripple Burst Mode operation maintains high efficiency at light loads while minimizing the output voltage ripple.

The converter turns on the internal switch immediately after the secondary diode current reduces to zero, and turns off when the switch current reaches the predefined current limit; the diode has no reverse-recovery loss.

Furthermore, since the switch is turned on with zero current, switching losses are minimized. The reduction in power losses allows the converter to operate at a relatively high switching frequency, which in turn, allows the use of a smaller transformer than would be required at a lower operating frequency. Overall, the LT8300 significantly reduces converter size compared to other solutions.

|

|

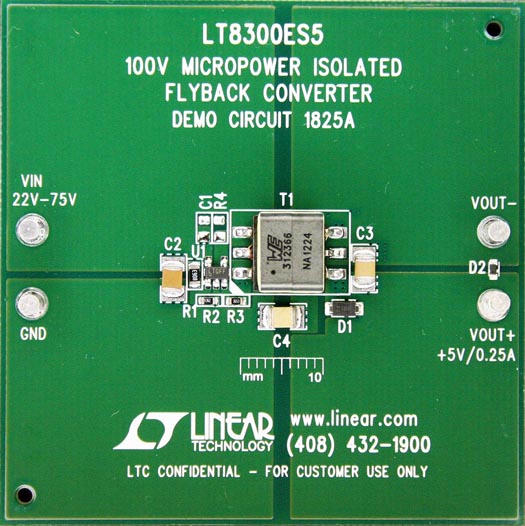

| Figure 3. | Demonstration Circuit of 22V to 75 V to 5 V/0.3 A Converter (See Figure 1). |

Figure 3 shows the standard demo circuit DC1825A for an isolated flyback using a small EP7 core transformer. The six key components are the input and output capacitors (C2, C3), output diode (D1), feedback resistor (R3), transformer (T1) and the LT8300. For the same application, a traditional flyback circuit would require, at minimum, eleven additional components, plus complicated start-up and bias power circuits in both the primary and secondary sides.

Low IQ, Small Preload and High Efficiency

As the load lightens, the LT8300 reduces the switching frequency until the minimum current limit is reached, and the converter then runs in discontinuous mode.

The LT8300 features an accurate minimum current limit and very small propagation delay. At very light loads, it further reduces the loss by running in low ripple Burst Mode operation, where the part switches between sleep mode and active mode. The typical quiescent current is 70 μA in sleep mode and 330 μA in switching mode, reducing the effective quiescent current.

|

|

| Figure 4. | Flyback Converter Optimized for Low Standby Power (6 V–12 V to 24 V/20mA). |

The typical minimum switching frequency is about 7.5 kHz, with the circuit requiring a very small preload (typical 0.5% of full load). Therefore, LT8300 power losses in standby mode are very low – important for applications requiring high efficiency in always-on applications. Figure 4 shows a solution that produces 20 mA at 24 V from a 12 V input. Efficiency peaks at 87%, and remains high at 84% with a 20 mA load, as shown in Figure 5.

|

|

| Figure 5. | Efficiency of the Converter in Figure 4. |

Conclusion

The LT8300 is an easy-to-use flyback converter with a rich set of unique features integrated in a small 5-lead TSOT-23 package. It accepts a wide input voltage range, from 6 V to 100 V, with very low shutdown current and standby power consumption. Boundary mode operation reduces switching loss, shrinks converter size, simplifies system design and offers superior load regulation. Other features, such as internal soft-start, accurate current limit, undervoltage lockout and internal loop compensation further facilitate an easy flyback converter design.

The LT8300 is ideal for a broad range of applications, from battery powered systems to automotive, industrial, medical, telecommunications power supplies and isolated auxiliary/housekeeping power supplies. The high level of integration yields a simple, low parts-count solution for low power flyback converters.