Yi Sun, Linear Technology

Design Note 517

Introduction

The LTC3883 is a single phase synchronous step-down DC/DC controller featuring a PMBus interface for digital control and monitoring of key regulator parameters. It has integrated MOSFET gate drivers and can function either standalone or in a digitally managed system with other Linear Technology PMBus-enabled parts.

The LTC3883 features:

- 4.5 V to 24 V input voltage range and 0.5 V to 5.5 V output voltage range

- ±0.5% output voltage accuracy over the full operational temperature range of –40°C to 125 °C

- PMBus interface with programmable voltage, current limits, sequencing, margining, OV/UV thresholds, frequency synchronization and fault logging

- Telemetry readback parameters including VIN, IIN, VOUT, IOUT, temperature and faults

- External voltage dividers to set the chip address and default switching frequency and the output voltage

- Input current sensing and inductor DCR autocalibration

1.8 V/30 A Single Phase Digital Power Supply with IIN Sense

Figure 1 shows a 7 V to 14 V input, 1.8 V/30 A output application that features inductor DCR current sensing. To improve the accuracy of the DCR current sense, the LTC3883 senses inductor temperature and compensates for the temperature coefficient of the winding resistance. This method ensures the accuracy of the readback current and overcurrent limit.

|

|

| Figure 1. | 1.8 V/30 A Single Phase Digital Power Supply with IIN Sense. |

The LTC3883’s control loop uses peak current mode control to achieve fast transient response and cycle-by- cycle current limit. Figure 2 shows the typical waveforms for a 10 A load step transient, resulting in only a 60 mV maximum deviation from nominal.

|

|

| Figure 2. | Transient Performance for a 10 A Load Step. |

Input Current Sensing

The LTC3883 features input current sensing via a resistor in series with the input side of the buck converter – a 5 mΩ sense resistor, as shown in Figure 1. The sense voltage is translated into a power stage input current by the LTC3883’s 16-bit internal ADC. In addition, an internal IC sense resistor senses the chip’s supply current at VIN, so it can provide both the chip and the power stage’s input current measurements.

Inductor DCR Auto-Calibration

|

|

| Figure 3. | DCR Auto-Calibration. |

The problem with conventional inductor DCR current sensing is that the tolerance of the DCR can be as large as ±10%, greatly limiting the current read back accuracy. To solve this problem, the LTC3883 uses a proprietary inductor DCR auto-calibration function. Figure 3 shows the simplified diagram of this circuit. The LTC3883 accurately measures the input current, IIN, the duty cycle (D) and the current sense voltage (VCS) and calibrates the real DCR value based on the relation:

![]()

With this auto-calibration method, the output current read back accuracy is within 3% regardless of inductor DCR tolerance.

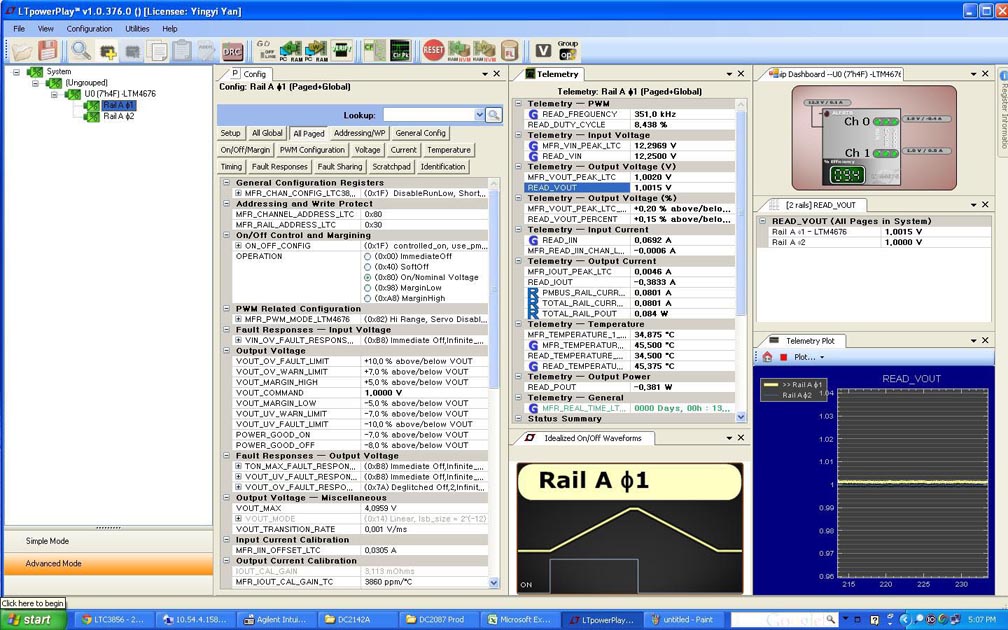

LTpowerPlay™ GUI

All power system management functions can be controlled by LTpowerPlay, a PC-based graphical user interface compatible with all of Linear’s power system management products (Figure 4). With LTpowerPlay, designers can easily program and control the entire power system without writing a line of code. With this tool, it is easy to configure any chip on the bus, verify system status, read the telemetry, check fault status and control supply sequencing. LTpowerPlay can be downloaded at LTpowerPlay.com.

|

|

| Figure 4. | PC-based graphical user interface LTpowerPlay. |

Conclusion

The LTC3883 combines a best in class analog DC/DC controller with complete power system management functions and precision data converters for unprecedented performance and control. Multiple LTC3883s can be used with other Linear Technology PMBus products to optimize multirail power systems. The powerful LTpowerPlay software simplifies the development of complex power systems. If dual outputs are needed, use the LTC3880 which shares common power system management features.