Joshua Yee, Linear Technology

Design Note 535

Introduction

For charging relatively low capacity batteries, or maintenance charging backup and keep-alive batteries, linear topology battery chargers are valued for their compact footprints, simplicity and affordability. Even so, there is a dearth of linear chargers that accept a 10 V or higher input voltage, leaving many industrial and automotive systems underserved.

Some switch mode solutions can accept high input voltages and switching topologies offer current and efficiency advantages, but they also incur significant costs in complexity and solution footprint. In the end, a switch mode solution is usually overkill for the low currents necessary in keep-alive systems or backup battery chargers. Furthermore, few are suitable for automotive and industrial applications up to 60 V.

|

||

| Figure 1. | Wide Range Linear Standalone Charger for 2-Cell Li-Ion Backup Battery. | |

LTC4079 is a wide input range standalone charger that can be powered by any DC source from 2.7 V up to 60 V, enabling CC/CV charging directly from 12 V and 24 V DC system rails, or even 48 V industrial supplies. Its marriage of simplicity and robustness allow it to easily satisfy the charging needs of keep-alive systems or backup battery solutions in these environments. Figure 1 is an example of a simple Li-Ion battery charger.

Fortitude and Flexibility, Neatly Packaged

The LTC4079’s charge voltage is resistor programmable, matching the flexibility of its wide input voltage range for practical purposes. The circuit is stable across the entire input voltage range with minimal input and output capacitance.

Using a single resistor on the PROG pin, charge current is programmable up to 250 mA and can be monitored in proportion to the PROG voltage. Charge termination functionality is familiar: timer-based, programmed via TIMER pin capacitance, or, C/10 current detection by connecting the TIMER pin to ground. /CHRG status signals termination by either method. The timer capacitor is also used for bad-battery detection.

|

||

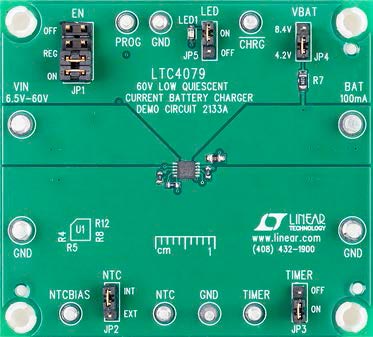

| Figure 2. | Complete Demo Board Circuit Footprint. | |

Temperature-qualified charging can be implemented via the NTC and NTCBIAS sensing network to round out the full charger circuit. The LTC4079’s thermally enhanced 3 mm × 3 mm DFN package includes an internal pass element, producing a compact and comprehensive solution. The complete circuit featured in Figure 2 shows its compact footprint.

Innovative Regulation for Utility and Facility

The LTC4079 includes a number of enhancements over conventional chargers with several distinctive charge current regulation methods. First, for wide range, but current-limited or high impedance sources, the input voltage can be regulated to at least 160 mV above the battery voltage (VIN(MIN) ≥ VBAT + 160 mV). Charge current is reduced to prevent the input voltage from collapsing below this value, maximizing charge current. No external components are required to exploit this internal regulation scheme. Figure 3 shows an example of temperature-compensated float charging a 12 V sealed lead acid battery stack from a solar panel, though any combination of input and battery voltages are possible.

|

||

| Figure 3. | Prevent Weak Sources from Being Overloaded with Input Voltage Regulation. |

|

The LTC4079's differential voltage regulation is particularly useful when very low power sources such as energy harvesters or small solar panels cannot continuously provide the minimum 10 mA charge current. Instead of the somewhat arbitrary halt to charging in the face of an undervoltage lockout (UVLO), this feature allows charging to continue whenever possible – a more efficient use of available input power.

For a more specific input voltage regulation setpoint, the enable input pin, EN, can servo to a resistor divider. As the input voltage reaches this setpoint, the charge current is reduced to prevent loading the source any further. In this manner, the enable input can be used to set a minimum operating voltage for a given source.

The final current regulation method – thermal regulation – is important for a monolithic device in general, but should be mandatory for a linear regulator. This is especially useful in harsher ambient environments and for high VIN/VBAT ratios, where the charge voltage is much lower than the nominal input voltage. Charge current is reduced until the IC junction temperature is reduced below 118 °C. See Figure 3 for an example circuit with input voltage regulation that prevents weak input sources from being overloaded.

Low Quiescent Current Draw

When charging, the LTC4079 consumes only 4 μA, maximizing energy transfer from the source to the battery. This is particularly important when transferring energy from a higher capacity battery to a smaller backup battery. In battery backup systems, the voltage feedback divider is taken out of the circuit to further unload the battery, reducing shutdown current to 10 nA (typical) and ensuring that capacity is not unexpectedly degraded in long-term standby or storage of the entire battery system. This makes the LTC4079 especially suited for low or zero-maintenance set-and-forget designs with embedded charging capability.

Summary

The LTC4079’s compact and comprehensive design is ideal for maintenance and keep-alive battery charging solutions, but it is not limited to these applications. Its rich feature set makes it easily adaptable to any number of charging roles in industrial, automotive, solar, medical, military/aerospace and consumer electronics.