Low Noise Silent Switcher Architecture Simplifies EMI Design

Automotive, transportation, and industrial applications are noise sensitive and demand low EMI power solutions. Traditional approaches control EMI with slowed down switching edges or lower switching frequency. Both have undesired effects, such as reducing efficiency, increasing minimum on- and off-times, and requiring a large solution. Alternative solutions such as an EMI filter or metal shielding add significant costs in required board space, components, and assembly, while complicating thermal management and testing.

Our low noise µModule® technology offers a breakthrough in switching regulator design. The LTM8003 regulator within the µModule package uses a proprietary Silent Switcher® architecture to minimize EMI emissions while delivering high efficiency at high switching frequencies. The architecture of the regulator and the internal layout of the µModule device are designed so that the input loop of the regulator is minimized. This significantly reduces the switching node ringing and the associated energy stored in the hot loop, even with very fast switching edges. This quiet switching offers excellent EMI performance while minimizing the ac switching losses, allowing the regulator to operate at high switching frequencies without significant efficiency loss.

|

||

| Figure 1. | A 5 V converter with a simple EMI filter at the input passes CISPR 25 Class 5. | |

This architecture, combined with spread spectrum frequency operation (SSFM), greatly simplifies the EMI filter design and layout, which is ideal for noise sensitive environments. Figure 1 shows a simple EMI filter on the input side, enabling the demo circuit to pass the CISPR 25 Class 5 standard with plenty of margin, as shown in Figure 2.

|

||

| Figure 2. | DC2416A demonstration circuit passes radiated EMI spectrum CISPR 25 Class 5. |

|

Continuous 3.5 A with Peak Current Capability 6 A

The internal regulator is capable of safely delivering up to 6 A of peak output current, and no extra thermal management – airflow or heat sink – is required for the LTM8003 to continuously support a 3.5 A load at 3.3 V or 5 V from a nominal 12 V input. This meets the needs of the battery-powered applications in industrial robotics, factory automation, and automotive systems.

Wide Operation Temperature Range from −40 °C to +150 °C

Automotive, industrial, and military applications require power supply circuits to operate continuously and safely in ambient temperatures over 105 °C or require significant headroom for a thermal rise. The LTM8003H is designed to meet specifications over a −40 °C to +150 °C internal operating temperature range. The internal overtemperature protection (OTP) monitors the junction temperature and stops switching when the junction temperature is too hot.

|

||

| Figure 3. | A 5 V, 3.5 A solution for 7 V to 40 V inputs using the H-grade version. Thermal imaging shows no need for bulky heat mitigation components. |

|

Figure 3a shows a 3.5 A, 5 V solution that operates from a wide-ranging 7 V to 40 V input. The thermal performance at a nominal 12 V input is shown in Figure 3b. The typical efficiency is above 92% with a 12 V input and 2 A load.

Negative Output −5 V from +3.5 V to +35 V Input

Figure 4 shows a solution for a –5 V, 4 A output from a nominal 12 V input, with a maximum of 35 V input. The BIAS pin should be connected to GND.

|

||

| Figure 4. | A –5 V supply from a +5 V to +35 V input delivers current up to 4 A. | |

Conclusion

The LTM8003 is a wide input and output range, low noise, 3.5 A step-down µModule regulator featuring the Silent Switcher architecture. Inputs from 3.4 V to 40 V can produce outputs from 0.97 V to 18 V, eliminating the need for intermediate regulation from batteries or industrial supplies. The pinout is specifically designed to be FMEA compliant, so the output stays at or below the regulation voltage during adjacent pin shorts, single-pin shorts to ground, or pins left floating. Redundant pins enhance electrical connections in the event a solder joint weakens or opens due to vibration, aging, or wide temperature variations, such as in automotive and transportation applications.

|

||

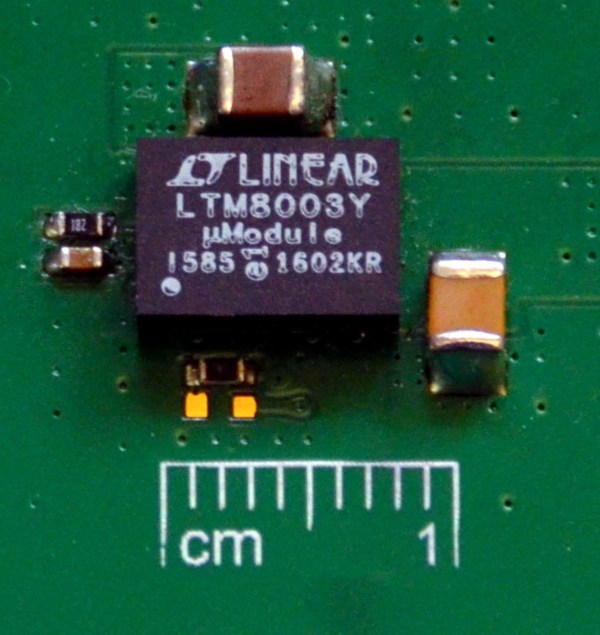

| Figure 5. | A complete step-down solution is barely larger than the 6.25 mm × 9 mm footprint of the LTM8003 µModule regulator. |

|

A complete solution fits a compact space not much larger than the 6.25 mm × 9 mm × 3.32 mm, BGA footprint of the LTM8003, including the input and output capacitors (Figure 5). The quiescent current of typically 25 µA and wide temperature operation from −40 °C to +150 °C (H-grade) make it ideal for circumstances where space is tight, the operational environment is harsh, and low quiescent current and high reliability are mandatory. Its features help minimize design effort and meet the stringent standards for industrial robotics, factory automation, avionics, and automotive systems.