Lance Turner

This wind turbine cost nothing virtually nothing to make and can produce enough power for small applications

There are many situations where you might need a small amount of electricity, for instance running gate openers, safety lights, water level indicators and other low-power devices.

While solar would seem like the ideal solution, quite often this is not possible due to location and shading problems.

Just such a situation arose when I decided to make our new gates automatic. There were just too many trees in the way for solar power to work, and I didn't want to run power some 30 metres or so from the house, as it would have meant digging a trench for the cables, which is almost impossible in our rocky ground.

Why have automatic gates anyway? Well, our driveway and the one next door share a common entrance, so to open the gates we have to block their driveway Also, the driveways are very steep, and starting off driving up from a standstill is not too good for the vehicle's clutch.

Besides, when an opportunity arises to install some form of new renewable energy device, how can I say no?

Anyway I decided to provide power to the electric gate openers from a small wind turbine. While we don't have many windy days, we do have one or two each fortnight where the wind blasts through for at least 24 hours solid, so I guessed that I should be able to power a device with such modest power requirements as a gate opener in this way.

The gate opener system itself is a home made job, using car windscreen wiper motors driving long brass threaded shafts.These run through a nut which is attached to the gate via a steel tube, bolt and two metal brackets.

The motors are hinged, and when they are run they either push the nut away from them or pull it toward them, thus opening and closing the gates.

The control circuit for this kit purchased from Qatley Electronics in Sydney and includes a courtesy light function, remote motors are hinged, and when they are control, and motor current sensing.

Too much turbulence

I briefly thought about what type of turbine I could install and how it would look.

Safety was another factor, having curious children who can climb just about anything. For these reasons I decided against buying a small horizontal axis turbine, they are too dangerous -when close to the ground and in touching distance, so I decided to install a Savonius rotor instead.

This type of vertical axis rotor is very robust and durable if built correctly, is relatively slow turning and can be easily built at home, without the hassles of aerofoil blade design and other problems associated with horizontal axis 'propeller' type turbines.

What's more, unlike a horizontal axis turbine, a Savonius is always facing the wind, and more importantly for this site, is not badly affected by turbulence, which is quite high where the turbine had to be located.

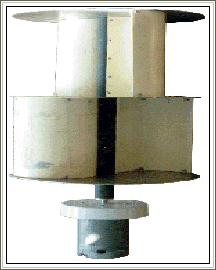

As can be seen from the photo, the turbine is mounted quite low due to it being on a residential block. While this is far from optimal, it should provide enough power for the gate openers providing it is used with a battery of relatively high capacity.

Making the turbine

The turbine was made from three disks of 1.2mm aluminium sheet 330mm in diameter and a length of 150mm diameter stormwater pipe about 600mm long.

This was cut in half in both directions, across and lengthways, to provide four vanes for the turbine. These vanes were then assembled between the three disks as shown in the photo. Small aluminium angle brackets and stainless steel pop rivets were used to hold it all together.

|

|

Here you can see the whole motor and rotor assembly before fitting to the mast and painting. Note how the vanes in the top section are rotated 90° to those in the bottom section and the motor does not yet have the plastic angle sections attached. |

The two vanes in the top section of the rotor are rotated 90 degrees to the bottom ones. This ensures that there is always at least one vane in a position to catch the wind, so the turbine is self-starting.

The axle for the rotor was a length of 40mm diameter water pipe.

This runs straight through the centre of all three disks, and the inner edge of each of the rotor vanes are riveted to it.

In the bottom end of the axle I pressed in (read hammered) an aluminium adapter bushing to allow the turbine to be connected directly to a generator.

The final assembly was very strong and rigid and was surprisingly well balanced.

While a central axle shaft is not considered optimal design for a Savonius rotor, it does have advantages, such as increasing turbine strength and allowing easy alignment in multi-stage rotors.

Savonius design

There are several variations of Savonius rotor that I have seen, all of which work well. The efficiency of a Savonius is only around 15 per cent but they are ideal for many situations. Some variations are shown below, looking down from the top of the turbine.

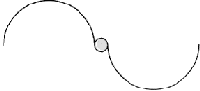

This is the design I use. it is very strong due to the central shaft, but slightly less efficient than the other two. However, the extra strength allows the rotor to be supported at one end only.

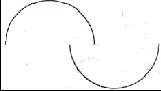

This design is also very simple, and can also be made easily from metal drums or pipe sections. The design is slightly more efficient than the one above as some of the air is deflected by the second vane as it exits the first one.

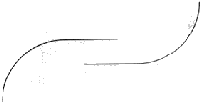

This is the most efficient Savonius design. It not only has the advantage of air being deflected twice like the design above, but also that the vanes act partly like an airfoil when they are edge-on into the wind, creating a small lift effect and thus enhancing efficiency. This design is much more difficult to build. requiring vanes rolled from metal sheet instead of being cut from drums or pipes.

To be continued