Application Note AND9100/D

September 2012

High power systems require the paralleling of IGBTs to handle loads well into the 10's and sometimes the 100's of kilowatts. Paralleled devices can be discrete packaged devices, or bare die assembled within a module. This is done for reasons of obtaining higher current ratings, thermal improvements, and sometimes for redundancy. Part-to-part process variations as well as layout variations, affect the static and dynamic current sharing of paralleled devices. It is important for the system design engineer to understand these issues so that a reliable system design can be achieved.

This paper will examine the types of variations due to process and temperature, and how they affect the power sharing of IGBTs. It will look at some empirical data and the implications on power sharing. The differences between IGBT modules and the paralleling of individually packaged IGBTs will also be examined.

The ability to share losses equally, is the primary goal in an application that requires paralleled IGBTs. If losses are not equally shared, the thermal differences between the devices will lead to other problems and the possible failure of the transistors. The imbalances come from two sources. Those internal to the IGBT are dealt with by selecting an appropriate device and those external to the IGBT are handled by good system design. This paper will address both of those sources.

![]() Download Application Note AND9100/D (954 Kb)

Download Application Note AND9100/D (954 Kb)

Related datasheets:

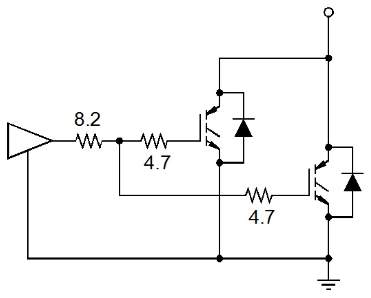

Combined Common and Separate Gate Resistors