Using LEDs has gained popularity as a method of saving power for general-purpose lighting, but an efficient method for driving them has also become a necessity. For example, Lumileds' Luxeon devices create lighting effects or room lighting. Providing power to a few LEDs may require only a current-limiting resistor, but illumination applications need a string of 20 or more LEDs to provide light over an area. Based on ON Semiconductor's NCP1200A, a 100-kHz PWM current-mode controller for universal offline power supplies, the circuit in Figure 1 provides a low-cost, offline constant-current source for powering multiple LEDs. Although designers typically configure it to provide a voltage source, in this application, the NCP1200A provides a constant-current source. Figure 2 and Figure 3 show close-ups of the circuit.

|

||

| Figure 1. | An offline constant-current source drives a string of high-output LEDs. | |

A full-wave bridge rectifier, D2 to D5, and filter capacitor C1 provide approximately 160 V dc to the conversion circuit, IC1, and its associated components. Resistor R3 alters the bias for IC1's current-sense pin and, at 6.2 kΩ, allows the use of a 1.2 Ω sense resistor for R6. Decreasing R6 not only reduces costs over a higher wattage sense resistor, but also improves the circuit's efficiency. Capacitor C3 stabilizes the feedback network's current and carries a 400 V rating in case of an open circuit in the LED string. An RC network comprising R5 and C4 provides a small amount of lowpass filtering to the CS pin.

|

||

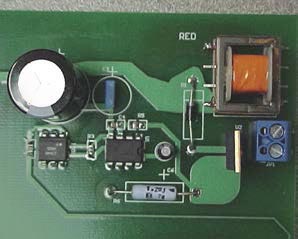

| Figure 2. | A close-up view of the circuit of Figure 1 shows inductor L1 in the upper right corner. |

|

Bleeder resistors R1 and R2 eliminate any shock hazard across the ac-line plug's prongs when you disconnect it. Although you can use a 1-MΩ through-hole-mounted resistor, two surface-mounted 500-kΩ series resistors cost less and provide the required track-to-track pc-board spacing for line-voltage applications. Use a capacitor rated for line-bypass service for capacitor C2. You can use any power MOSFET with a suitable breakdown voltage and a low on-resistance, such as an MTD1N60E or IRF820, for Q1. Inductor L1, a 500-µH device, should be able to operate at 100 kHz and handle more than 350 mA of continuous current. You can use an inductor from Coilcraft's RFB1010 or DR0810 series of surface-mount inductors, or you can experiment with inductors manually wound on suitable core materials. As an option, adding optoisolator IC2 allows microcomputer-controlled illumination dimming using pulse-width modulation of IC1's feedback terminal, Pin 2.

|

||

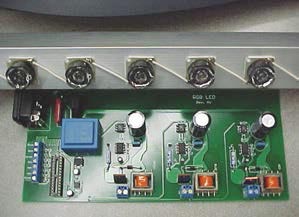

| Figure 3. | This version of the circuit comprises three constant- current driver channels. An LED light-bar assembly is above the pc board. |

|

To understand the economic motivation for using LEDs as illuminators, compare the light output of a string of 20 1 W, white Luxeon emitters with a standard incandescent light bulb. Each LED provides 45 lumens, or 900 lumens for a string of 20 LEDs. The average forward voltage per LED is 3.42 V for a power dissipation of 1.197 W each at a forward current of 350 mA. Thus, the 20-LED string dissipates 23.94 W. Factoring in a conservative 80% efficiency for the power supply, the power the system consumes becomes 28.73 W for a light-emission-efficiency value of 900 lumens/ 29 W or 31 lumens/W. The Luxeon emitters also carry a rating for 100,000 hours, or approximately 11 years, of operation.

In contrast, a standard 60 W Philips incandescent light bulb produces 860 lumens for 1000 hours, or just over a month, at an efficiency of only 14 lumens/W. From a power-consumption viewpoint, the LED-based design is twice as efficient as the incandescent-bulb-based design and thus reduces power consumption and cost. In addition, the LED design imposes no additional maintenance costs for replacement bulbs and labor.