By Graham Prophet

EDN-Europe

Researchers from one of Europe’s largest e-mobility projects have successfully realised a fully-integrated electric vehicle drivetrain without the need for costly rare earths in the permanent magnet synchronous motor

Four years ago researchers from nine European countries and more than 30 partner organisations, universities and businesses came together with a single goal: to develop a high-performing and reliable powertrain for electric vehicles that is energy-, resource- and cost-efficient. A large part of the €36million project, dubbed ‘MotorBrain’, was dedicated to eliminating the need for rare earth metals in commercially viable engines for hybrid and electric vehicles.

“Rare earth metals produce powerful and reliable permanent magnets, which is why they are used by almost every major hybrid and electric vehicle manufacturer today,” says Dr. Yves Burkhardt, R&D engineer at Siemens Corporate Technology and researcher on the EU-funded MotorBrain project. “Yet their availability is limited – around 90% of the world’s supply is controlled by China – and they can be difficult and potentially hazardous to mine, making them a key cost driver for electric motors.”

The motor sub-team of the project, led by Siemens, immediately discounted induction motors due to limitations in their design and set about investigating alternatives to rare earth permanent magnets in synchronous motors.

“Our results showed that ferrite-based magnets, although inferior to rare earth magnets, could still achieve the same or even better power density than in induction motors but with the other benefits that synchronous motors can offer,” Dr. Burkhart says.

For example, the simpler single tooth winding, which can be applied to synchronous motors, requires less wire and the manufacturing process is easier to automate since each tooth can be wound in an identical fashion and pieced together later. In the manufacture of induction motors, however, the iron ring of the stator must be produced whole with complex windings distributed around multiple lamination teeth.

“We can use fewer components and make the manufacturing process quicker and easier. For the end user this means a lighter, cheaper, more efficient motor,” he says.

But MotorBrain is not just about the motor. The project team sought to reduce the cost and number of components, as well as speed up manufacturing of the entire powertrain, using a novel integration approach.

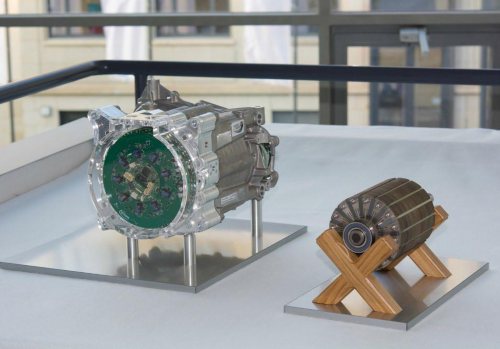

“In earlier generations of electric vehicle powertrains, the steering and power electronics are separate, but we integrated the electric motor, the gear box and the control of the system into a single housing,” Dr. Burkhardt says. “With no plugs and cables and fewer external interfaces that need sealing, we created a common system that saves on space and parts and is cheaper and more robust.”

This integrated powertrain system also enabled the project team to apply more sophisticated software with better control algorithms for improved performance.

“Project MotorBrain has made considerable leaps forward in the design and manufacture of powertrains for hybrid and electric vehicles – whether the motor incorporates rare earth metals in the permanent magnets or not,” he says. “I believe we can expect to see similar electric powertrain systems commercialised in the next few years.”