Linear's corporate environment

EDN: Other companies envy your profitability. Numerous financial journals have commented on that, as well. The corporate environment that you have created seems like an obvious way to have a successful business, yet I can’t think of another company that does what Linear does especially for 30+ years.

Swanson: You may or may not know that I am the technical fly-weight in the company. When we started the company we said that we were going to make products and be first to market with them, and that they would be better than existing solutions. Don’t tell me what the product costs – tell me what the product is worth. So we quickly realized that pricing products based on their functional value, while doing a sanity check on what it costs is a good approach. So many people start with the cost and mark it up 2 or 3 times and think that that is a good business model. We always ask, ‘What is it worth to the customer?’ If we sell a customer something for $4 that replaces something for which he is now paying $5, why isn’t everybody happy? Why would you care if it costs me $0.50 or $1? I just gave you a better product. I think that might have been a new kind of culture.

Dobkin: And at the same time, there is a lot of infrastructure for the product. If they needed help, it was there right away, including the design engineer, if needed to fly out to customers to help them.

EDN: When I was a circuit design engineer in the 1970s and 1980s, I would get calls from the receptionist when a vendor in the lobby wanted to see me. If it was the guy or gal who just would drop off literature and disappear when I needed help, then I would ask that they leave the literature for me. But if they were the guy or gal who would stay close and support me after I bought the product and put me in touch with the factory people who would solve my problem, then I would see them even if they did not have an appointment. Designers are busy people trying to get products out the door within a very tight schedule framework.

Swanson: Well that has been so important to us, but obviously we have great products. But competitors have great products too. In this analog-challenged world, we have been so good at transferring our knowledge leverage to customers. I will occasionally see the big customers at social events. They always tell me how much they depend upon our design and field people. Our field people are brilliant FAEs. I tell the customers that those technical experts are what you are paying for. Look at our P&L statement, SG&A, and R&D. Manufacturing costs are less than that. So don’t open up our part to see how big the silicon is or how big the package is or how many leads are on it. Look at the things that you love about it. That’s what you’re paying for. They might go away grumbling but thinking about that.

Dobkin: In terms of efficiency, we can’t design a product without good test engineers and good product engineers. It’s the whole package that gets the product out into the customer’s hands and keeps it running smoothly. Right from the beginning we realized that we needed good techs, good product engineers; the whole thing. Also, our products have longevity. It’s nice to have engineers that also have longevity in case we need to answer questions about something that happened 10 years ago.

EDN: What I see quite a bit is acquisitions and technology flowing out of this country. We don't really manufacture much anymore, but technology was big for us.

Dobkin: We manufacture our own wafers; to be a good analog supplier we need to have control of a lot of specialized processes that don’t come from foundries. We’ve got processes that we developed specially designed for analog. 40 years ago everybody did analog on the same bipolar process; it’s not the same now.

Swanson: One of the challenges going forward is you can’t afford to spend $2B to set up a new fab to support $100M of business. There are some things that good business sense says that ‘You can’t build a fab to do that.’ But here’s a $100M piece of business we can make money at, but we’ll have to depend on somebody else’s fab. But it is true today that 95% of what we do – part of the secret sauce is in the wafer fab.

|

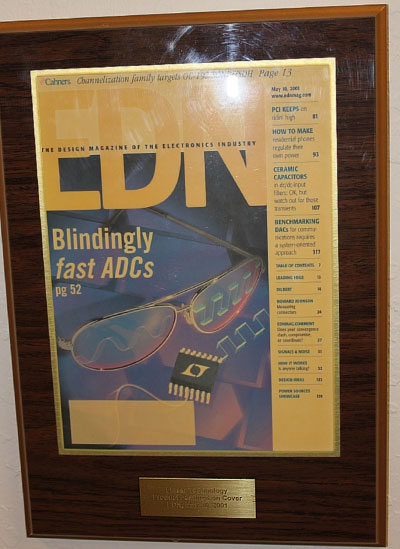

| Linear Technology’s high speed ADCs were touted on the coverof this May 10, 2001 edition of EDN. |

EDN: Well, you guys have been around a lot of years and that says a lot about your company and the respect it has in the industry.

Swanson: When you think about it, we have to be proud of what we’ve accomplished. And a lot of it was, ‘Wow, this is what we said we would do.' We set these high goals. Some say 'Nobody sets goals nowadays,' but then a little while later they say, 'We’ve almost done it!'

Probably the greatest thing is the culture we have with these really bright engineers who choose to work here. They could work anywhere, and they have rough days and good days and there are times when we won’t do exactly what they want, but they get most of what they want. And they feel that it’s an inspiring environment and they stay with us, and they innovate, and they do things that other people can’t do.

EDN: It’s so refreshing for me to witness your unique corporate culture when I meet with your marketing engineers and design engineers, a real bright group, and I can see that they are all very happy here at Linear. You listen to all their ideas and give them opportunities to run with an idea. It’s almost, but not quite, like a mom-and-pop organization – certainly a close relationship between management and designers.

Swanson: We need to keep that. National got to be a $1B company and they said ‘we have to have matrix management…’ they totally messed things up. Even then I thought that just because we are a $1B company, I don’t understand why we have to change anything. Some of those things they wanted to change were the reasons we got to $1B. Why would you change that? Well they did anyway.

So, I think we can go a long way with this structure. I hope that when I’m gone that they don’t change very much of it.

EDN: Look how far you’ve come.

Dobkin: At our size we’ve kept the same structure that we had when we were smaller. And we’re growing with it. And I think the management here has seen that this structure works. There’s no reason to change it.

Swanson: The only thing we changed a few years ago was when we got to a point where we said ‘Everybody can’t report to Bob (Dobkin).’ We broke the company into product groups: power, signal conditioning, and so forth. Then power got so big that we split it in two because if you’ve got two really smart guys – it’s got to be better than one smart guy. So we get to the point where we dice things up to an area where they can really focus, because we have to beat the competition.

Dobkin: And we have to keep the customers happy.

EDN: With that attitude, you can’t lose.

Swanson: With good people, you let them do the right thing and stay out of their way and help them when they need you to be there.

Dobkin: Our attitude in the beginning was to help the customer. Even if he doesn’t buy your product, he will come back to you next time. Do him wrong and he will never come back to you next time.

Swanson: I remember in the early days, our FAEs would design in a TI $0.50 part. I would say we have a $1 part – what are you doing? The FAE would say that ‘He doesn’t need our $1 part Bob (Swanson). We have 3 of these really good linear parts designed in and he needed a linear regulator, and the $0.50 part is just good enough and if I try to force a part on him that he doesn’t need, it will come back to bite us.’ Well, I reluctantly gave in to that.

EDN: It’s great that that type of culture filters down to all your employees from you guys.

Swanson: That’s a culture I had to learn. I used to say ‘Hey, we’re in business here and we could be out of business and our success isn’t official – what do you mean you designed in a TI part?’ They convinced me that it was the right long-term thing, and we’re not going out of business next month!

EDN: It’s all about transparency to the customer and being honest with them and of course, you have to make money, as well. But that’s building relationships.

Swanson: I’ve learned over the years that designing in the parts that are the right parts that the customer needs and not stuff that they don’t need – in the end goes to our credibility.

IC design and circuit design

EDN: I had interviewed a bunch of people about the early days of early IC technology when I wrote my first feature article for EDN, Analog: Back to the Future, and the new engineers nowadays have great tools like simulation, etc., but what I see in my travels is that engineers are losing that feel and insight for the transistor and what it is doing inside that IC. So many designers just plop down an RF amplifier or data converter without a full understanding of the functionality and what’s happening inside that IC.

Simulations are excellent in today’s electronics world, but I find that many designers do not know the true limitations of that tool. What do you think about that with regards to IC design and also circuit design? First let’s look at IC designers as a case.

Dobkin: For a lot of analog functions, the simulation is only so good. You still have to understand what you’re doing when you make an IC. Simulation is much better than it used to be, but there are still some things that don’t simulate like the interaction of thermal effects in power devices. You have to know what you’re doing there. When you’re doing really high speed circuits, you need to understand what’s going on because, not only are you simulating transistor circuits, but you’re simulating the package and everything outside to make it actually work properly.

From the customer’s point of view, many of them know more about IC simulation than transistor circuit simulation. Some do, of course, but not to the depths that you need to design an IC. Plus, if you’re designing an IC, you’re using lots of MOS devices, as well as Bipolar. The small signal MOS devices are not readily available as discrete devices. We, as designers, have to know the transistors because that’s our business. We have to know how to simulate them and when the simulation doesn’t work, we have our own SPICE internally that’s used, as well as commercial simulators. And we also give our LTspice out free to our customers so they can simulate our models when they’re doing a system design. We probably have the world’s most popular SPICE with over half a million downloads.

Swanson: That’s an interesting point that Steve brought up. What I learned in the early days is that the analog guys really had to understand the silicon, more so than the digital guys did. When we talk about the digital guys, sit them down at the computer and they can immediately design things. And I understand, over the years, how we’ve had to advance our tools because the products got so complex that engineers said, ‘I can’t do this anymore without these tools.’ And I knew the tools were imperfect, but the question you asked was, ‘As we deal more and more with better simulation and better tools, are the engineers losing that feel for the silicon that they had to have 15 years ago?’

Dobkin: No (emphatically stated) – they’re not losing it. Circuits are more complicated and they still have to understand the silicon and how it interacts with the transistor next to it. The only thing that we’ve done is that we made it easier to get it right the first time. And there are still things that the simulator doesn’t handle. So we do the simulation and we do it to the best of our ability and then we do the rest of the debugging on the chip because if the simulators were perfect, everything would work the first time. And that happens a very low percentage of the time.

Editor’s note: During this interview with these two industry icons, I sensed that they know their place in the industry and in their company and effectively used the talent of their employees in a way that I personally have never seen in my 42 years in electronics. They are strong, talented, and intelligent leaders, but with a touch of humility and compassion for their employees from which other companies can learn a great deal. There is a really good book written by two Japanese gentlemen (One of them a Nikkei Electronics editor) which says a great deal about the corporate culture at Linear entitled, “The Company That No One Leaves.” This book gives wonderful insight into one of the key reasons this company has had such success over the last 34 years.

I sincerely wish Bob Swanson and Bob Dobkin many more years of success. I know that someday they will want to retire, but their influence on Linear Technology’s corporate culture will carry on to ensure the continued success of their company in the future.