Evan Lerner

University of Pennsylvania

Technology tends to move toward the bigger and better, cramming more and more features into a given product. But sometimes, less is more.

Robots are often called on to do the jobs that are too dirty or dangerous for humans, such as examining the Fukushima Daiichi nuclear power plant after it experienced multiple meltdowns in the wake of a tsunami. The most advanced robots, however, were stymied by the same problems as their human counterparts; the massive amounts of radiation inside would make it a one-way trip. Smaller, simpler robots are now being developed with such applications in mind.

|

||

| Matthew Piccoli. | ||

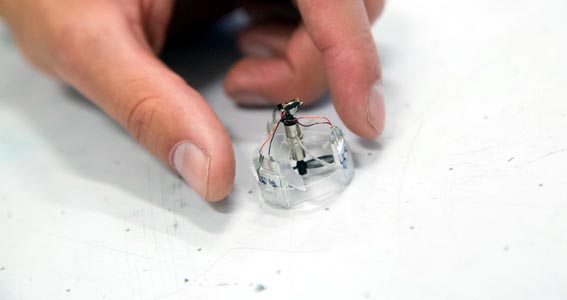

Researchers at the University of Pennsylvania’s School of Engineering and Applied Science have now taken this effort a step forward, debuting the world’s smallest self-powered controllable flying vehicle: Piccolissimo.

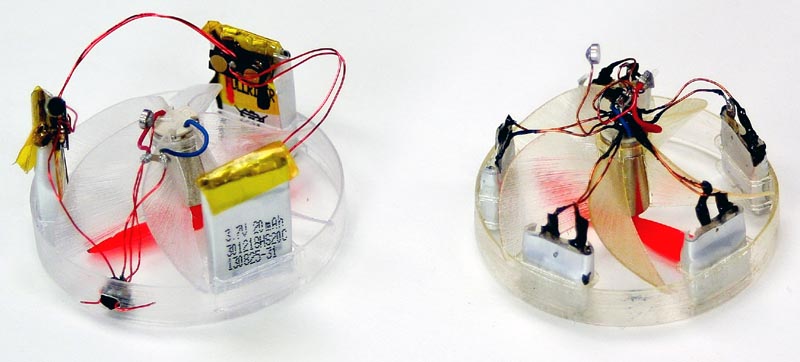

Italian for “tiniest,” Piccolissimo is the brain child of Matt Piccoli, a graduate student in professor Mark Yim’s ModLab. The robot comes in two sizes; the smaller weighs less than 2.5 grams and is about the width of a quarter, while the larger, steerable version is about 2 grams heavier and a centimeter wider.

The string of adjectives qualifying Piccolissimo as the “smallest” is necessary due to the concerted effort in miniaturizing flying robots. Harvard’s RoboBee, for example, is a few millimeters smaller than the steerable Piccolissimo, but is tethered to a terrestrial power source, limiting its range of motion.

Enabling directional control on such a tiny frame is an equally big challenge, but one that the ModLab is particularly equipped to address. One of the lab’s specialties is “underactuated” robots, ones that achieve the greatest range of motion with the fewest motors possible.

|

||

| Piccolissimo has two moving parts: a body and a propeller. An infrared signal tells the propeller how fast to spin. |

||

To that end, Piccolissimo has only two moving parts: a propeller and the body of the robot itself. Made out of light, 3D-printed plastic, Piccolissimo’s body spins in the opposite direction as the propeller. Precisely timed speed changes, controlled by an infrared signal, can therefore turn the robot one way or another.

“The body spins around 40 times per second, while the propeller spins about 800 times per second,” Piccoli says. “Since the propeller is mounted off-center on the vehicle body, the propeller’s center, and therefore the location of its thrust, also spins around 40 times per second. If we increase the propeller speed every time the body is facing ‘6 o’clock’ and slow down the propeller every time the body faces ‘12 o’clock,’ the average torque tries to turn the body towards ‘12 o’clock.’”

While Piccolissimo’s small size limits how much it can carry – about a gram’s worth of payload – it is enough for a small camera or other types of sensors. Piccoli also thinks that the robot’s unique mode of locomotion could be an asset in this area as well.

“Spinning vehicles are pretty terrible for carrying people, but pretty fantastic for carrying sensors,” Piccoli says. “It's common practice to make a simple sensor, then spin it around, like radar dishes at airports. We get this feature for free, so we could take a line-scan camera, like in a barcode reader, put it on the vehicle body, and get a 360-degree panorama. These cameras are simpler and smaller than a normal 2D camera, and yet we’d get a better field of view.”

Piccolissimo is emblematic of the creative thinking originating at PERCH, the Penn Engineering Research and Collaboration Hub, where ModLab is one of the three main robotics groups. Their neighbors include the Kod*Lab, which develops legged and otherwise biologically inspired robots, and the Multi-Robot Systems Laboratory, MRSL, which focuses on creating autonomous ground and aerial robots, and designing bio-inspired algorithms for swarming behavior. PERCH is based on the third floor of the Pennovation Center, a business incubator and laboratory that brings together researchers, innovators, and entrepreneurs for the commercialization of research discoveries.

The latter is directed by Vijay Kumar, the Nemirovsky Family Dean of Penn Engineering, whose vision for teams of teams of flying, cooperating robots working agriculture, disaster relief, and search and rescue is well-documented. Cross-pollinating ideas with ModLab is another step toward realizing that vision.

“With Piccolissimo, Dean Kumar's dream of 100 robots flying together in PERCH could actually happen both in terms of size and cost,” Yim says. “And in terms of search and rescue, having 100 or 1,000 small controllable flyers could explore more of a disaster site than a single big, expensive one.”