Sam Davis

Power Electronics

A collaborative research project is making use of temperature fluctuations to produce electricity.

Generating electricity in unique ways is getting the attention of scientists at the University at Buffalo and MIT. Collaborative research project led by the University at Buffalo and the Institute of Semiconductors (IoP) at the Chinese Academy of Science (CAS) uses a tab – a triboelectric nanogenerator. MIT scientists use temperature fluctuations to produce electricity.

The UB and CAS approach generates electricity from a small metallic tab that, when attached to the body, is capable of generating electricity from bending a finger and other simple movements. The tab – a triboelectric nanogenerator – is described in a study published online in the journal Nano Energy [1].

“No one likes being tethered to a power outlet or lugging around a portable charger,” says lead author Qiaoqiang Gan, Ph.D., associate professor of electrical engineering in UB’s School of Engineering and Applied Sciences. “The human body is an abundant source of energy. We thought: ‘Why not harness it to produce our own power?’” (Figure 1).

|

||

| Figure 1. | Shown is a prototype of the triboelectric nanogenerator. (Credit: Nano Energy) |

|

Triboelectric charging occurs when certain materials become electrically charged after coming into contact with a different material. Most everyday static electricity is triboelectric. Researchers have proposed numerous nanogenerators that utilize the triboelectric effect; however, most are difficult to manufacture (requiring complex lithography) or are not cost effective.

The tab that the UB and CAS team are developing addresses both of those concerns. It consists of two thin layers of gold, with polydimethylsiloxane (also called PDMS, a silicon-based polymer used in contact lenses, Silly Putty, and other products) sandwiched in between.

Key to the device is that one layer of gold is stretched, causing it to crumple upon release and create what looks like a miniature mountain range. When that force is reapplied – for example, from a finger bending – the motion leads to friction between the gold layers and PDMS.

“This causes electrons to flow back and forth between the gold layers,” says another lead author, Yun Xu, Ph.D., professor of IoP at CAS. “The more friction, the greater the amount of power is produced.” The study describes a small tab (1.5 cm long, by 1 cm wide). It delivered a maximum voltage of 124 V, a maximum current of 10 µA, and a maximum power density of 0.22 mW/cm2. That’s not enough to quickly charge a smartphone; however, it lit 48 red LED lights simultaneously.

Co-authors of the study include Huamin Chen at IoP and CAS, along with Nan Zhang, a Ph.D. student at UB.

Because the tab is easily fabricated, Zhang is leading a team of UB undergraduates that is tasked with improving the tab’s performance. The team plans to use larger pieces of gold, which when stretched and folded together are expected to deliver even more electricity.

Researchers are also working on developing a portable battery to store energy produced by the tab. They envision the system serving as a power source for various wearable and self-powered electronic devices.

The research is supported by the U.S. National Science Foundation, the National Basic Research Program of China, the National Natural Science Foundation of China, Beijing Science and Technology Projects, Key Research Projects of the Frontier Science of the Chinese Academy of Sciences, and the National Key Research and Development Plan.

MIT Research

The team at MIT came up with a novel way to convert temperature fluctuations into electrical power. Instead of requiring two different temperature inputs at the same time, the new system takes advantage of the swings in ambient temperature that occur during the day-night cycle. This differs from thermoelectric devices that generate power when one side of the device is a different temperature from the other. (Figure 2).

|

||

| Figure 2. | The thermal resonator is filled with a material that captures heat, generating electricity from the temperature difference over the course of the day (Credit: Melanie Gonick). |

|

The new system, called a thermal resonator, could enable continuous, years-long operation of remote sensing systems – for example, the researchers say, without requiring other power sources or batteries.

The findings are being reported in the journal Nature Communications, in a paper by graduate student Anton Cottrill, Carbon P. Dubbs Professor of Chemical Engineering Michael Strano, and seven others in MIT’s Department of Chemical Engineering.

“We basically invented this concept out of whole cloth,” Strano says. “We’ve built the first thermal resonator. It’s something that can sit on a desk and generate energy out of what seems like nothing. We are surrounded by temperature fluctuations of all different frequencies all of the time. These are an untapped source of energy.”

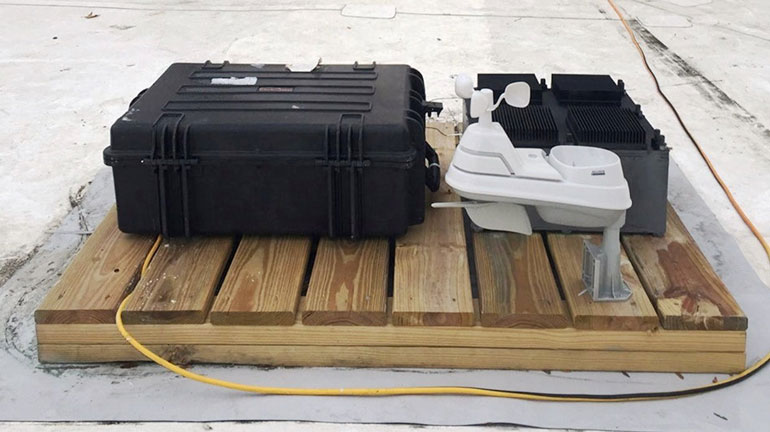

While the power levels generated by the new system so far are modest, the advantage of the thermal resonator is that it does not need direct sunlight; it generates energy from ambient temperature changes, even in the shade. That means it is unaffected by short-term changes in cloud cover, wind conditions, or other environmental conditions, and can be located anywhere that’s convenient (Figure 3) – even underneath a solar panel, in perpetual shadow, where it could even allow the solar panel to be more efficient by drawing away waste heat, the researchers say.

|

||

| Figure 3. | The thermal resonator weather station sits on the roof of an MIT building, generating power through temperature fluctuations. (Credit: Justin Raymond) |

|

The thermal resonator was shown to outperform an identically sized, commercial pyroelectric material (an established method for converting temperature fluctuations to electricity) by a factor of more than three in terms of power per area, according to Cottrill.

The researchers realized that to produce power from temperature cycles, they needed a material that is optimized for a little-recognized characteristic called thermal effusivity – a property that describes how readily the material can draw heat from its surroundings or release it. Thermal effusivity combines the properties of thermal conduction (how rapidly heat can propagate through a material) and thermal capacity (how much heat can be stored in a given volume of material). In most materials, if one of these properties is high, the other tends to be low. Ceramics, for example, have high thermal capacity but low conduction.

To get around this, the team created a carefully tailored combination of materials. The basic structure is a metal foam, made of copper or nickel, which is then coated with a layer of graphene to provide even greater thermal conductivity. Then, the foam is infused with a kind of wax called octadecane, a phase-change material, which changes between solid and liquid within a particular range of temperatures chosen for a given application.

A sample of the material made to test the concept showed that, simply in response to a 10 °C temperature difference between night and day, the tiny sample of material produced 350 mV and 1.3 mW – enough to power simple, small environmental sensors or communications systems.

“The phase-change material stores the heat,” says Cottrill, the study’s lead author, “and the graphene gives you very fast conduction” when it comes time to use that heat to produce an electric current.

Essentially, Strano explains, one side of the device captures heat, which then slowly radiates through to the other side. One side always lags behind the other as the system tries to reach equilibrium. This perpetual difference between the two sides can then be harvested through conventional thermoelectrics. The combination of the three materials – metal foam, graphene, and octadecane – makes it “the highest thermal effusivity material in the literature to date,” Strano says.

While the initial testing was done using the 24-hour daily cycle of ambient air temperature, tuning the properties of the material could make it possible to harvest other kinds of temperature cycles, such as the heat from the on-and-off cycling of motors in a refrigerator, or of machinery in industrial plants.

“We’re surrounded by temperature variations and fluctuations, but they haven’t been well-characterized in the environment,” Strano says. This is partly because there was no known way to harness them.

Other approaches have been used to try to draw power from thermal cycles – with pyroelectric devices, for example – but the researchers say the new system is the first that can be tuned to respond to specific periods of temperature variations, such as the diurnal cycle.

These temperature variations are “untapped energy,” says Cottrill, and could be a complementary energy source in a hybrid system that, by combining multiple pathways for producing power, could keep working even if individual components failed. The research was partly funded by a grant from Saudi Arabia’s King Abdullah University of Science and Technology (KAUST), which hopes to use the system as a way of powering networks of sensors that monitor conditions at oil and gas drilling fields, to give one example.

“They want orthogonal energy sources,” Cottrill says – that is, ones that are entirely independent of each other, such as fossil fuel generators, solar panels, and this new thermal-cycle power device. Thus, “if one part fails,” for example if solar panels are left in darkness by a sandstorm, “you’ll have this additional mechanism to give power, even if it’s just enough to send out an emergency message.”

Such systems could also provide low-power but long-lasting energy sources for landers or rovers exploring remote locations, including other moons and planets, says Volodymyr Koman, an MIT postdoc and co-author of the new study. For such uses, much of the system could be made from local materials rather than having to be premade, he says.

This approach “is a novel development with a great future,” says Kourosh Kalantar-zadeh, a distinguished professor of engineering at RMIT University in Melbourne, Australia, who was not involved in this work. “It can potentially play an unexpected role in complementary energy harvesting units.

“To compete with other energy harvesting technologies, always higher voltages and powers are demanded,” he adds. “However, I personally feel that it is quite possible to gain a lot more out of this by investing more into the concept… It is an attractive technology which will be potentially followed by many others in the near future.”

The team also included MIT chemical engineering graduate students Albert Tianxiang Liu, Amir Kaplan, and Sayalee Mahajan; visiting scientist Yuichiro Kunai; postdoc Pingwei Liu; and undergraduate Aubrey Toland. It was supported by the Office of Naval Research, KAUST, and the Swiss National Science Foundation.