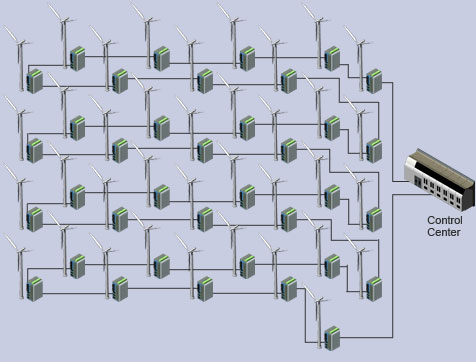

Offshore wind power applications are similar to typical onshore wind turbine projects. Both types require careful planning during the construction phase, and it is best to manage wind turbine systems remotely from a central control center. In order to keep the installation cost at a reasonable level, most wind turbine sites are made up of many turbines. In fact, the turbines are often erected in rows, in the same way that crops are planted.

System Requirements

Location

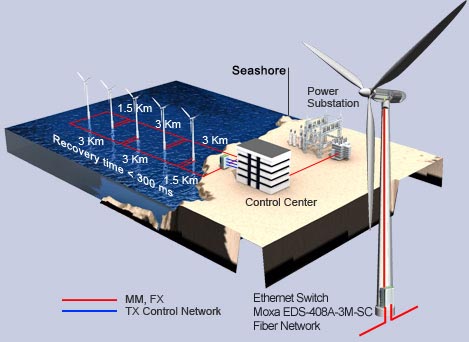

Typically, most offshore wind turbine projects are located along coastlines where the wind speed is greater than onshore. However, offshore environments are often subject to critical conditions, such as corrosion and extreme temperatures, making safety certification and long MTBF a must. Since wind power plants require a huge investment of time and money, designers must select high quality products with specialized features.

Transmission Distance

Electric transmission lines and network control lines are buried under the seabed. In some cases, the first wind turbine site is located more than 3 km from the control center. An inefficient network design can dramatically increase the cost of cabling. For this reason, determining a good location for each wind turbine, and implementing a reliable network with nonstop network communication can have a big impact on future maintenance costs.

Maintenance

The cost of sending engineers to a wind turbine site to collect power meter data or to conduct regular maintenance can be very high. This is particularly true since ships or helicopters must be used for transportation. Traditionally, maintenance technicians had to be winched down to the wind turbine platform from a helicopter if the sea was too rough to approach the structure by boat. Not only is it expensive to rent a helicopter or boat, but it is also extremely dangerous to send engineers into such a hazardous area. Moreover, if the weather conditions are particularly fierce, then work on the wind turbine may need to be postponed for an unknown amount of time. Being able to set up a reliable control network with a SCADA system can greatly simplify the task of managing and controlling a wind turbine farm.

Control Network

Ethernet is the perfect solution for reducing the total cost of setting up and maintaining a communication network. By using Ethernet, engineers do not need to learn proprietary protocols, which are only supported by specific vendors at a high price. Engineers can also concentrate on determining which product functions and features are needed.

Ethernet is the perfect solution for reducing the total cost of setting up and maintaining a communication network. By using Ethernet, engineers do not need to learn proprietary protocols, which are only supported by specific vendors at a high price. Engineers can also concentrate on determining which product functions and features are needed.

Typical wind turbine control network

Typical network diagram (I)

Typical network diagram (II)